PET Bottle Perforator PRESTO - PF-44/80

Price upon request

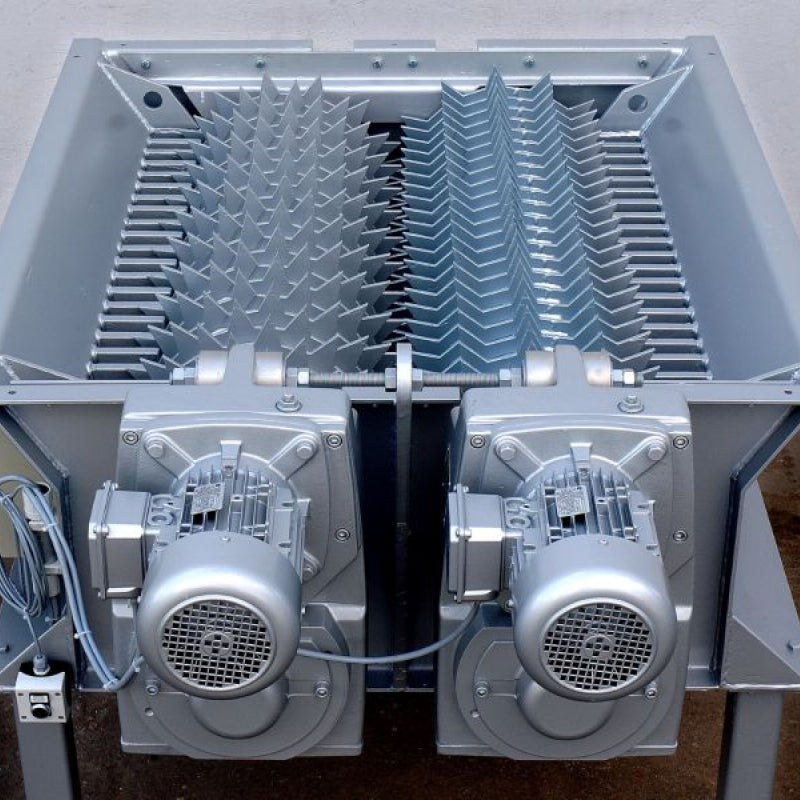

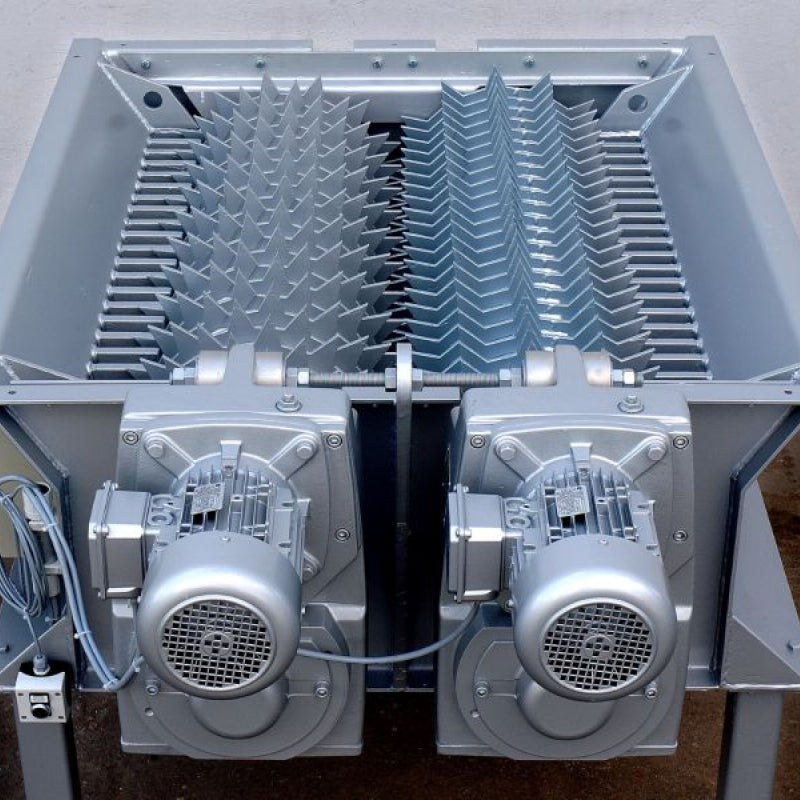

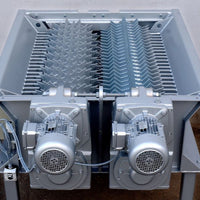

In order to optimise the compaction process, two rotating spiked shafts that are moving in the opposite direction of each other draw in the PET bottles or bottles packed into plastic film bags. The perforated material is transferred directly onto the conveyor of a horizontal baler, a static compaction system or a static auger compactor.

Features

- PET bottle perforators allow you to destroy PET bottles and prepare them for compaction

- The use of the system in combination with other compactors leads to optimum compaction results.

- PET bottle perforators can be fed manually, by a

forklift, conveyor or wheel loader. - Other plastic containers can also be perforated effectively.

Product Description

Guaranteed powerful performance

The robust steel construction and quality workmanship ensure durability and reliable

function. Two revolving wear-resistant spiked drums pull the PET bottles or beverage tins into the machine. High-quality components ensure reliable function, low maintenance and quite operation < 65 dB (A). Of course our paints are lead and chromium free, and you can select the colour of your choice.

Models (Table)

| Model | PF 44 | PF 80 |

|---|---|---|

| Length (L) mm | 2155 | 2175 |

| Width (B) mm | 1320 | 1320 |

| Height (H) mm | 685 | 685 |

| Feeding opening (lxb) mm | 1380 x 1200 | 1380 x 1200 |

| Feeding volume, max mm | 0.8 | 0.8 |

| Rev. per minute n/min | 13 / 13 | 13 / 13 |

| Machine weight kg | 1450 | 1500 |

| Motor power rating kw | 4.4 | 8 |

| Electrical power supply | 3 L / N / PE; 400 V,50 Hz, 50 A | 3 L / N / PE; 400 V,50 Hz, 50 A |

Enquiry Form

Product: PET Bottle Perforator PRESTO - PF-44/80

You may also like

Perforated Cardboard Packaging - HSM C400

Perforated Cardboard Packaging - HSM P425

PET Bottle Perforator HSM - PF-600/1200