Briquetting Pressses Hocker - BrikStar C5-14

Price upon request

BrikStar C. C like “Compact”

The dust and chips produced are compressed by your BrikStar C briquetting press into high-quality briquettes. The BrikStar reliably and without a hitch around the clock - of course with minimum energy input for maximum briquette output.

Features

- Produce up to 170 kg briquettes. Every hour!

- Produce your heating material yourself

- Safe storage and disposal of critical dusts

Product Description

Briquettable materials

The BrikStar C briquetting press processes dust and chips from wood

- Wood

- Straw

- Paper

- Tissue

- Plastics

- and many other cellulosic materials.

Additional Information

What are the advantages of the BrikStar?

You invest in quality. Over 2,500 BrikStar briquetting presses are proving themselves worldwide in tough continuous operation. They are robust, clever operators with an economical control system and an optimum energy/output ratio.

Versatile Material Processing

With the BrikStar C, you can process materials such as wood, paper, tissue, plastics, straw, etc., and much more into quality briquettes.

Reduce Volume

Reduces the volume of the material ratio 1:10 (max.)

Equipped for Continuous Operation

The BrikStar C7 and C11 presses are equipped as standard with oil coolers for 24-hour operation.

All-Inclusive Standard Equipment

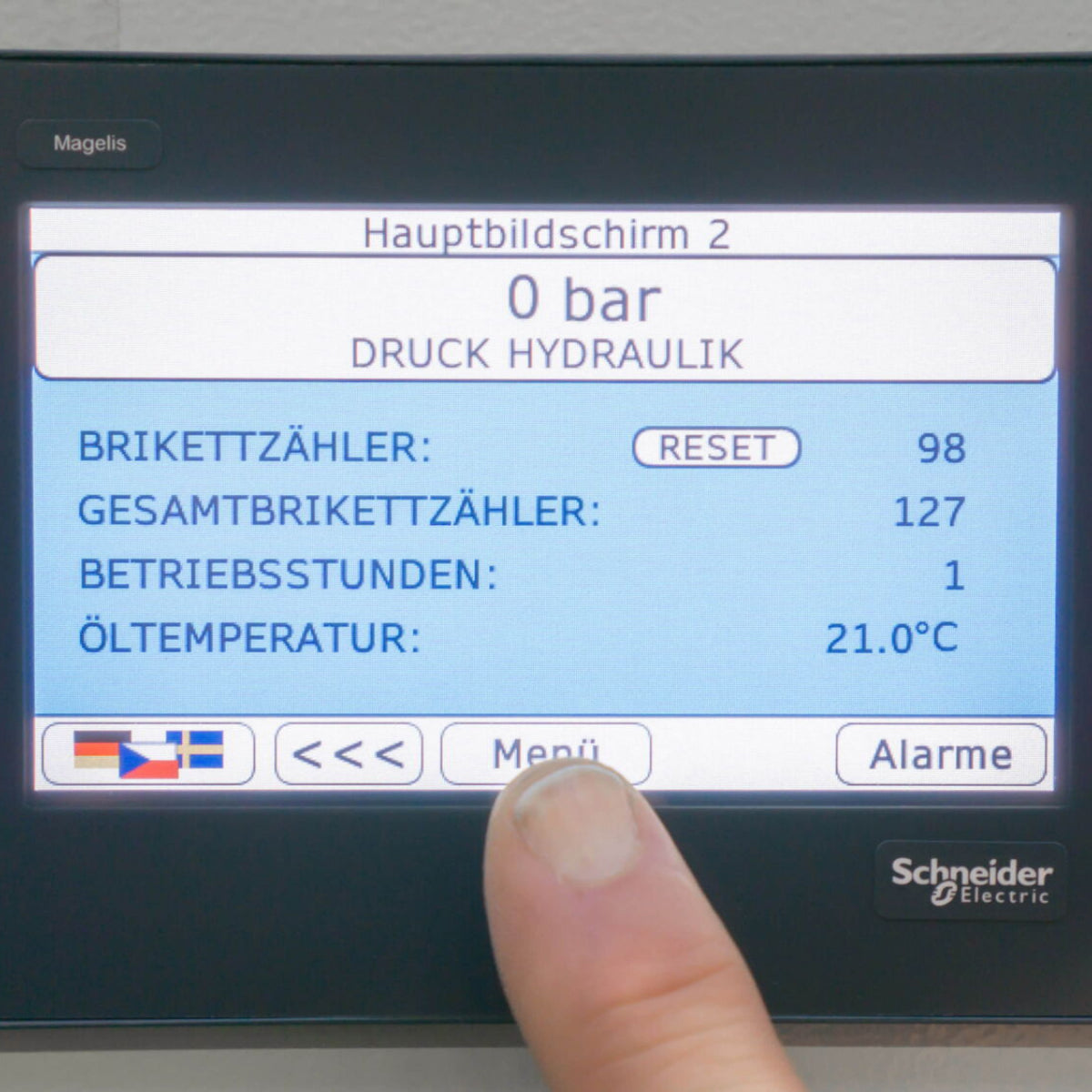

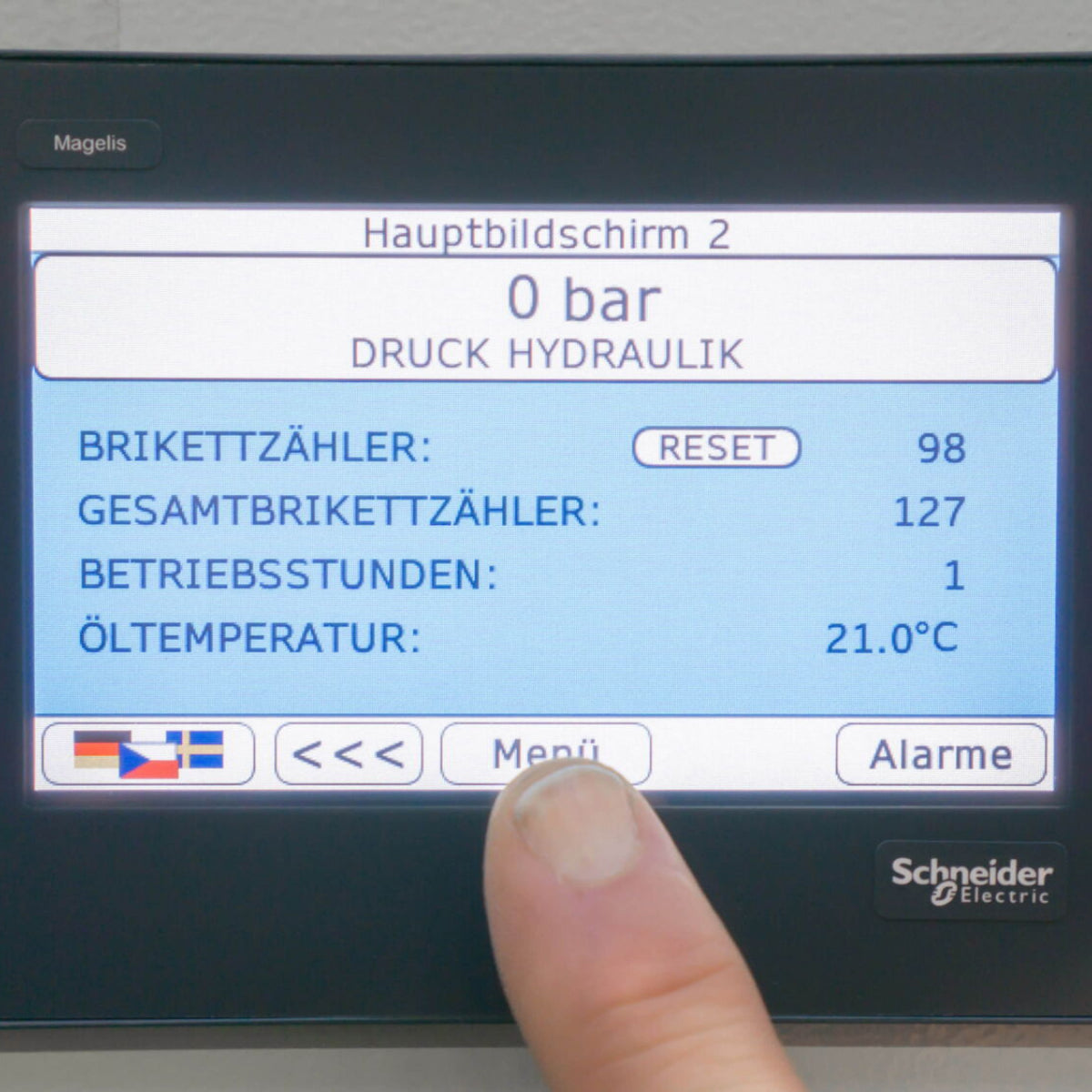

Operating hours and briquette counter, press pressure display, temperature monitoring, automatic briquette length control, and much more.

Reliable Feeding

The generously dimensioned screw trough and the stable dosing screw ensure continuous material feed.

Simple Operation via Touch Panel

Access to all information and settings with a few finger movements.

Light and Rough Material

The clever design allows the processing of many organic materials.

Long Lifecycle

Designed in an extremely compact and robust frame construction.

Maintenance-Friendly

Easy access to the machine from all four sides.

Plug’n Press

Your BrikStar is delivered ready to plug in.

Practical and Safe

Inspection door with safety shut-off as shutdown for safe operation.

Up to 170 kg/h Throughput Capacity

Entry from BrikStar C3 (max. 50 kg/h) up to BrikStar C11 (max. 170 kg/h).

Silent Hydraulics

Anti-vibration dampers reduce the operating sound.

Large Briquette Diameter

65 mm enables optimum conveying, storage, and thermal utilization of the briquettes.

Main Press Cylinder with Extra Power

Excellent briquette quality even with less easily briquettable materials.

Automatic Briquette Length Control

Ensures consistently high briquette quality and length even with changing material types.

Functional Reliability

Vertical corner plate linings prevent bridging in the container.

Automatic Operation

A rotating paddle detector monitors the automatic start/stop function and reduces operating hours and energy consumption.

Enquiry Form

Product: Briquetting Pressses Hocker - BrikStar C5-14

See it in action

You may also like

Briquetting Presses Hocker - BrikStar CS 09-09