10PCB Overband Magnets

Price upon request

Overband magnet separators are extremely effective in extracting tramp metal to protect processing machinery and to separate and upgrade product feed.

In recycling, quarrying and allied industries there is always the possibility that tramp metal will find its way into the product stream. If tramp metal continues into the crusher or shredder, machinery can be damaged resulting in expensive downtime and repairs.

Product Description

Commonly used worldwide mounted on machinery for the separation and upgrading of materials including plastics, wood, rubber, glass, computer components and aggregate.

The principal of operation is simple:

Conveyor belt revolves continuously around a permanent or electromagnet. The product on the main conveyor or feeder passes under the overband and tramp metals are lifted clear by the magnet.

The metals are then swept out of the magnetic field by the cleated conveyor belt and discharged at a point either parallel to, or at right angles to the side of the conveyed product. Ideally the overband will be positioned in-line as the material being conveyed will be in virtual suspension and “dwell time” under the magnet is optimum.

Due to space restrictions within plant, overbands are commonly fitted across the conveyor, so overband magnets are manufactured in-line and cross-belt to suit customer requirements.

Dimensions

- Width: 650 mm

- Height: 750 mm

- Length: 850 mm

Weight

Enquiry Form

Product: 10PCB Overband Magnets

You may also like

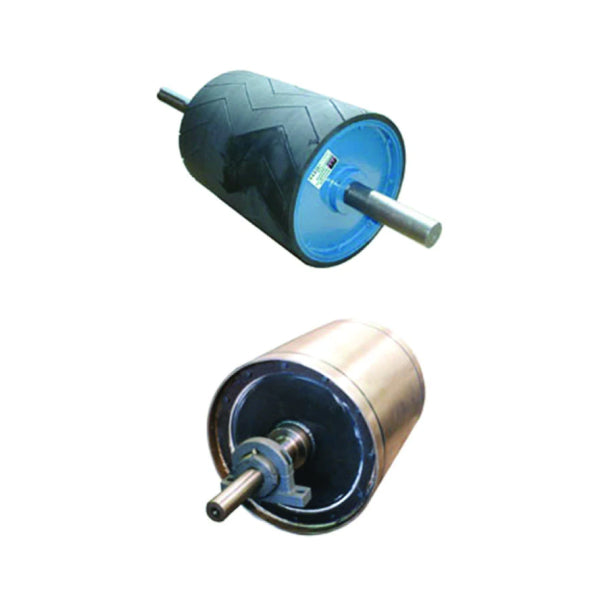

PPH Pulley Magnets

PSM - Suspension Block Magnets