Eddy Current Separators - Stokkermill

Price upon request

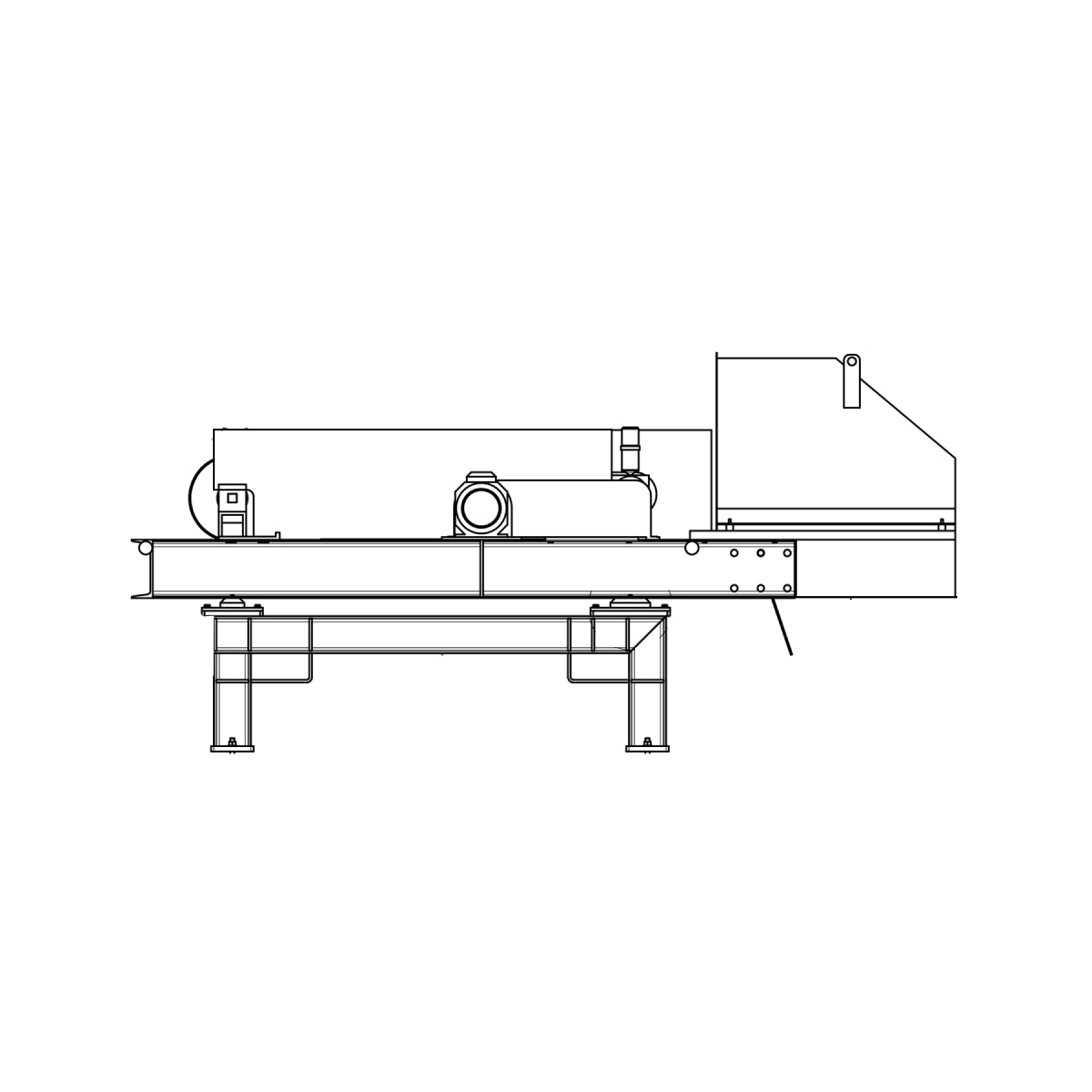

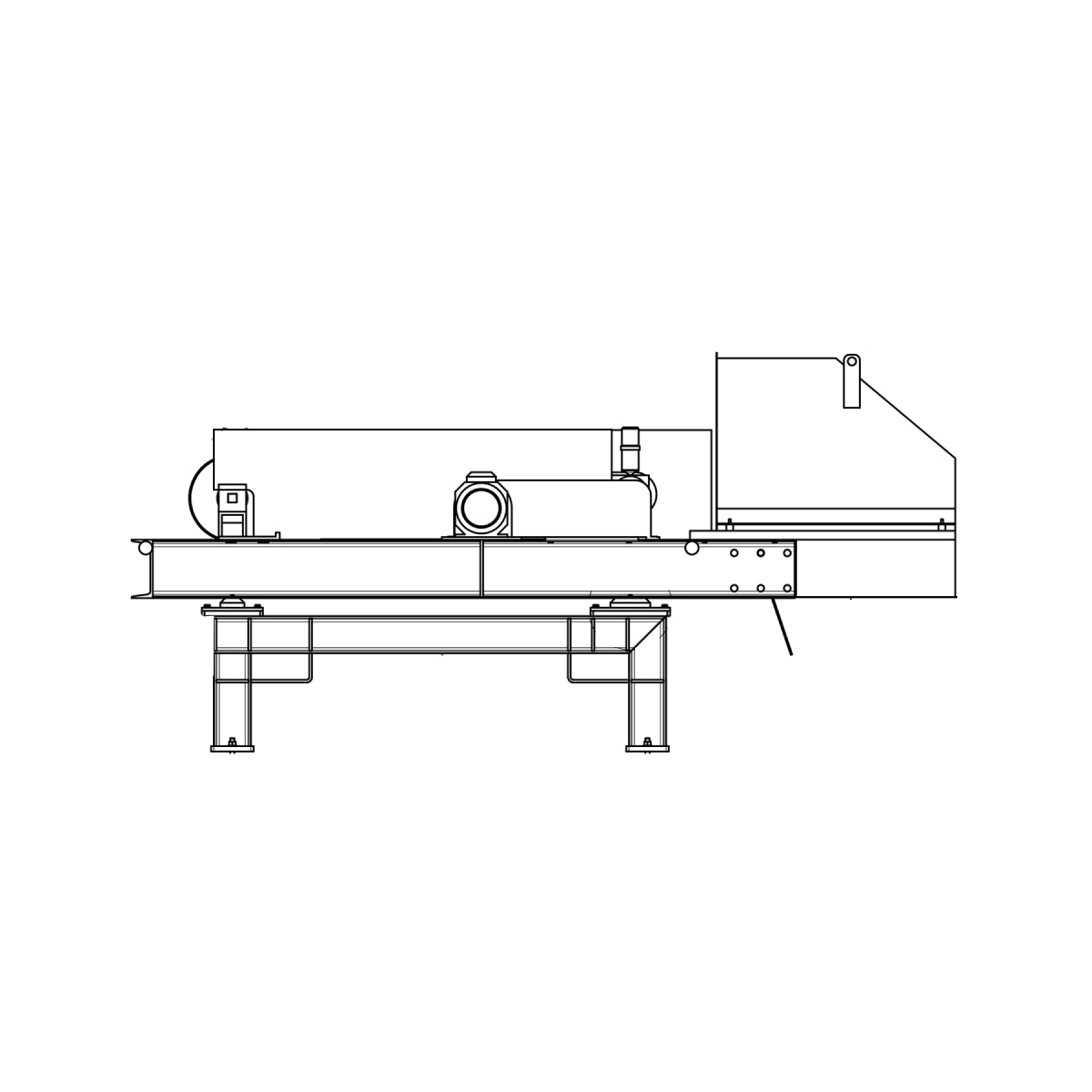

Separator non ferrous metal separation Eddy Current for Metal particles recovery

Separator Non Ferrous Metals separation enable to recover the metal fraction (indicatively from 1 mm to 300 mm) sorting from the final stream in a recycling process. The Eddy Current separator have an extremely wide field of use and they can separate small non-ferrous metal particles. A magnetic rotor is placed inside a conveyor belt which, by turning at high speed, creates a considerable induced current field which moves the non-ferrous metal particles with low electrical conductivity away from the material flow.

Features

- Low operating costs

- Limited maintenance

- Reliability and precision of operation

Models

EC 500

- Work surface: 500 x 1950 mm

- Power: 5.5 kW

- Dimensions: 3665 x 1651 x 1442 mm

- Weight: 1600 kg

EC 750

- Work surface: 750 x 1950 mm

- Power: 5.5 kW

- Dimensions: 3755 x 1891 x 1442 mm

- Weight: 1790 kg

EC 1000

- Work surface: 1000 x 1950 mm

- Power: 5.5 kW

- Dimensions: 3865 x 2099 x 1442 mm

- Weight: 1900 kg

Enquiry Form

Product: Eddy Current Separators - Stokkermill

You may also like

Eddy Current Separators - Bunting

The Eddy Current Separator is used widely in the recycling industry to either recover or remove non-ferrous metals from non-metallic materials. Different designs enable the separation of small (down to...

Stainless Steel Separator - Bunting

Bunting’s Stainless Steel Separator was developed after its engineers designed and patented a neodymium rare earth magnetic roll that produces an ultra-strong magnetic force to attract even large and heavy...