Mixed Construction Waste HL I 1222 - Husmann

Price upon request

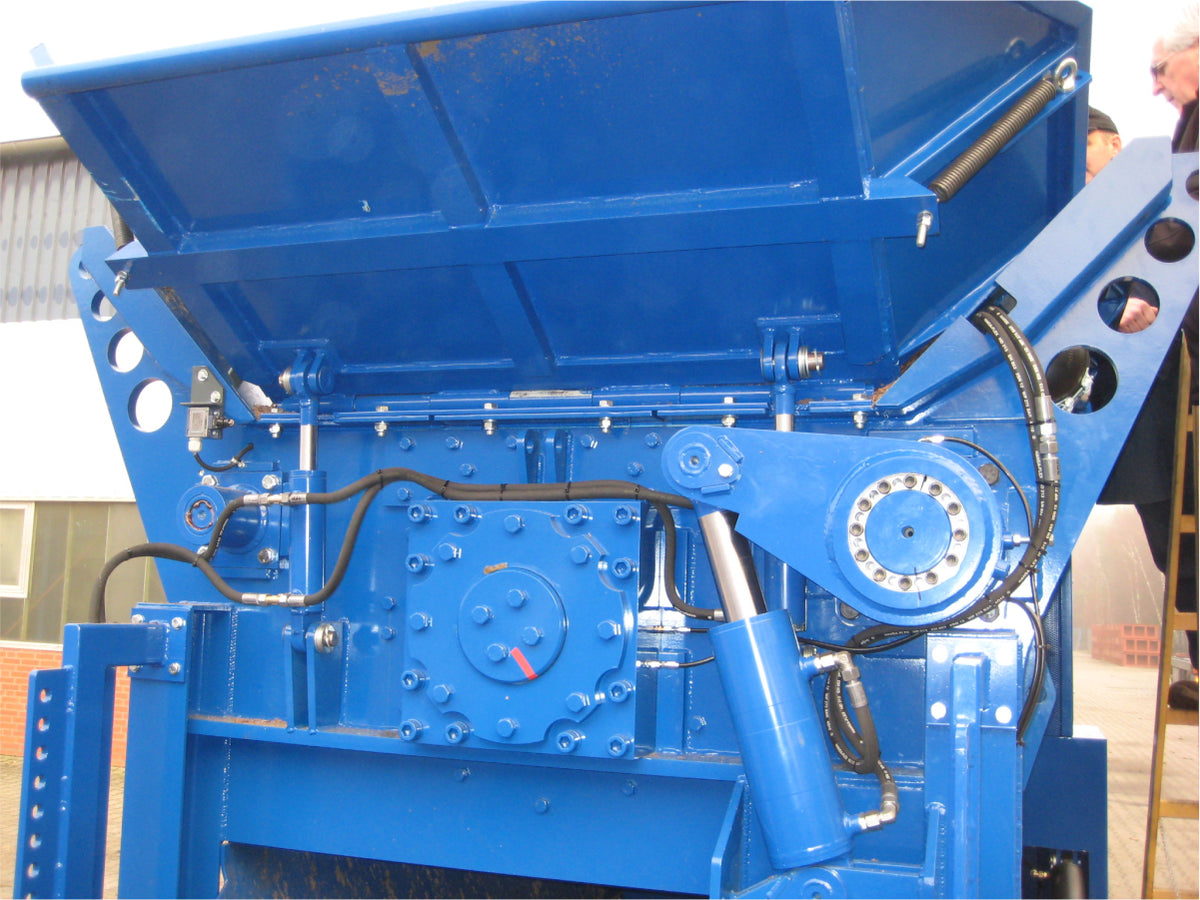

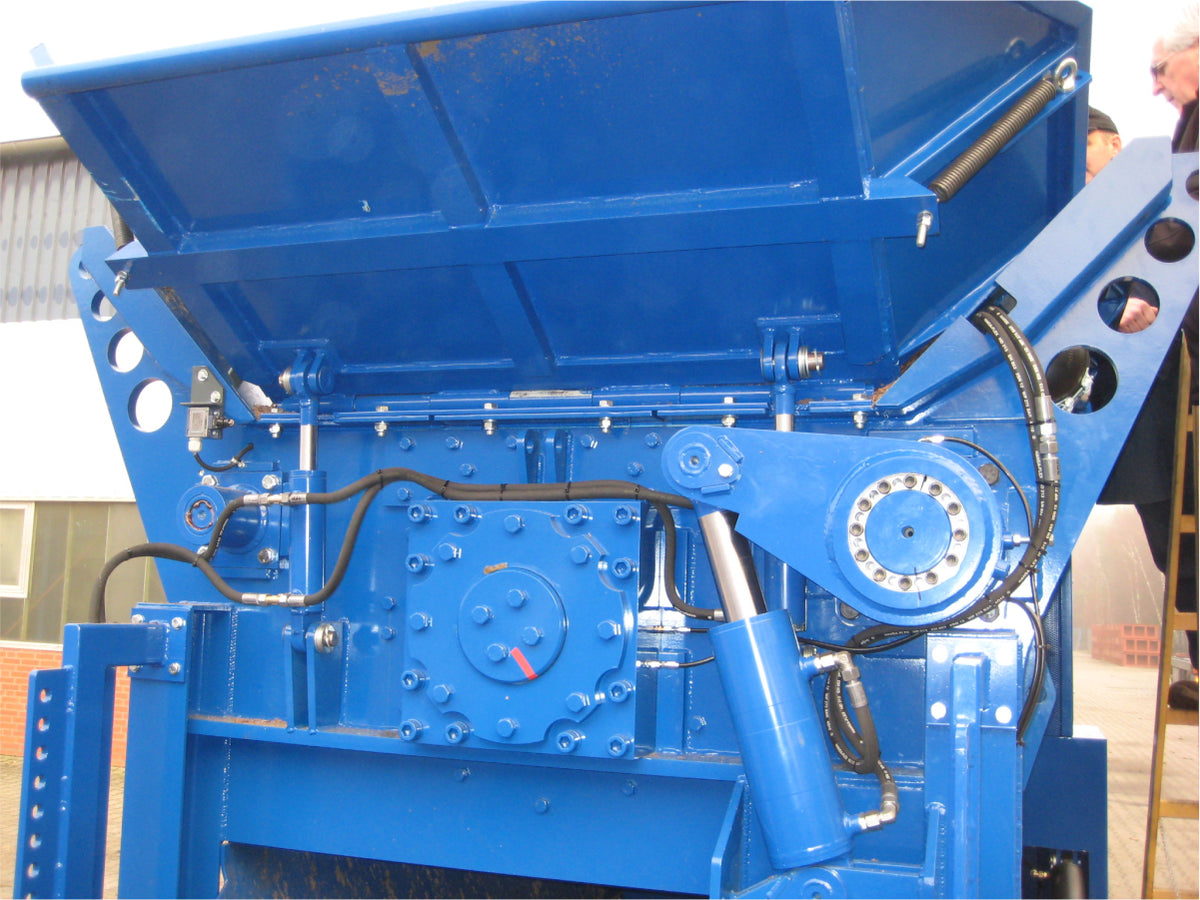

Crusher HL I 1222 Especially for general, bulky, mixed construction waste, green waste and also waste wood. The feeding material is fed into a hopper, which simultaneously feeds the slowly rotating crushing shaft.

Product Description

The designation »HL I« is used for the Single-Shaft Crusher. Accordingly, the term »HL II« designates the twin-shaft machines. All crushing machines are offered on a steel profile construction with hook-lift system. Even versions with crawler track, a three-axle trailer chassis or static machines on steel supports are also used.

The crusher of the HL series was constructed as a pre-crusher for timber, pallet wood, household waste, bulky waste, industrial waste, green waste and roots. Long-term experience with the production of comminution machines at Husmann led to this highly universal and economical crushing machine.

In order to transport the machine, the transport belt can be folded in. The discharge belt is part of the basic equipment as well as the oil tank heating and monitoring devices for the transport belt, oil temperature and oil circuit.

The slow-speed Single-Shaft crusher of the type HL I stands out for its intelligent hydraulic system with performance control and automatic speed adjustment of 20 up to 35 rpm. The drive unit with Sauer hydraulic pumps and slowly running gear motor achieves a long service life. A torque of 90.000 – 130.000 Nm, level monitoring, temperature monitoring and overload protection are further quality features of the crusher!

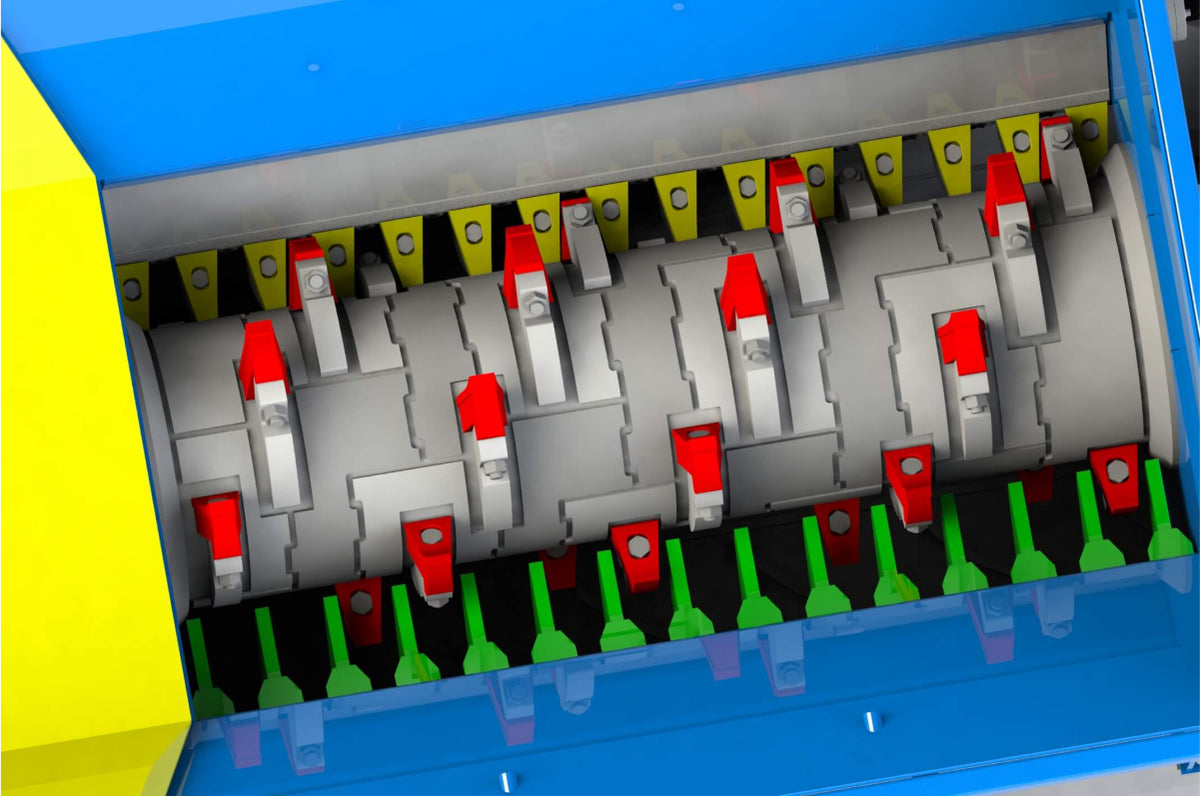

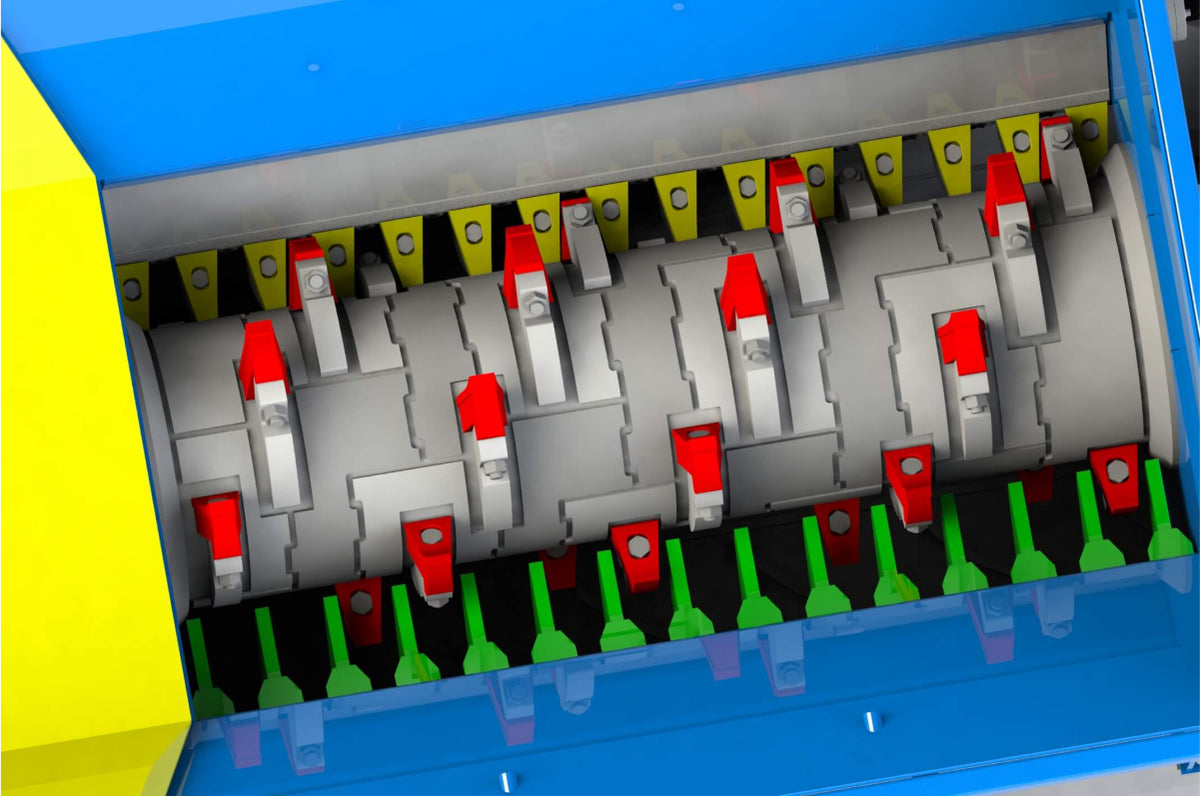

The switchable and also in automatic mode running comminution process can activate the crushing shaft in both directions of rotation. The feeding material is fed into the hopper, which simultaneously feeds the crushing shaft. Bolted crushing tools guarantee highest throughput even in the case of the most difficult feeding material. The hydraulically adjustable side comb with bolted teeth destines the cutting gap to the crushing shaft, thereby also the particle size respectively the quality of the feeding material. The bolted crushing tools guarantee a rapid tool change.

Models

The »HL I« series with a crusher shaft stands out with quick-change, bolted blades, and a flexible, adjustable side comb. The system is protected against breakagedue to the automatic reversing system in combination with the ejection unit.

One-wave crusher HL I 1222 – hook lift

Machine frame:

- Welded steel profile construction on a U-frame with a hook holder according to DIN 30722

Lift axis:

- hydraulically lowerable wheel axle with drawbar

- without StVZO

- with operation via the remote control

Engine:

- CAT turbo diesel with an output of P = 205 kW, valid Euro emissions standard

Diesel tank:

- Two tanks, content: 300 liters

Dimensions:

- see installation plan and scope of delivery

- Overall length: 10,800 mm

- Total length of transport position: 8,600 mm

- Width: 2,550 mm

- Height: approx. 2,800 mm

- Throw-in height: 2,700 mm

Weight:

- Dead weight approx. 18,500 kg, depending on the equipment

One-wave crusher HL I 1222 – electrical / stationary

Machine frame:

- Stable steel welded construction according to the application

Engine:

- Electric motor with an output of P = 200 kW

Dimensions:

- see installation plan and scope of delivery

- Machine set up according to customer requirements

Weight:

- Dead weight approx. 16,000 kg, depending on the equipment

One-shaft crusher HL I 1222 – chain chassis

Machine frame:

- Welded steel profile construction mounted on a chain chassis

Driving drive chain chassis:

- Hydraulically driven, maneuverable via remote control

Engine:

- CAT turbo diesel with an output of P = 205 kW, valid Euro emissions standard

Diesel tank:

- Two tanks, content: 300 liters

Dimensions:

- see installation plan and scope of delivery

- Total length: approx. 10,450 mm

- Transport position: approx. 8,300 mm

- Width: 2,500 mm

- Height: approx. 3,340mm

- Throw-in height: 3,200 mm

Weight:

- Dead weight approx. 26,000 kg, depending on the equipment

One-shaft crusher HL I 1222 – three-axis chassis

Machine frame:

- Welded steel profile construction mounted on a three-axle chassis

Chassis:

- 3-axis low loader unit approx. 18 tons.

TÜV decrease for 80 km / h axis - compressed air braked

- ABS brake system

- Intermediate line – Compressed air brake system for 80 km / h axle

Engine:

- CAT turbo diesel with an output of P = 205 kW, valid Euro emissions standard

Diesel tank:

- Two tanks, content: 300 liters

Dimensions:

- see installation plan and scope of delivery

- Total length: approx. 11,840 mm

- Transport position: approx. 9,700 mm

- Width: 2,500 mm

- Height: approx. 3,400mm

- Throw-in height: 3,350 mm

Weight:

- Dead weight approx. 23,500 kg, depending on the equipment

Options

The basic equipment of the HUSMANN one-wave crusher can be adapted to the wishes and applications of the customers using various accessories. This includes, among other things, an individual discharge conveyor belt, a TÜV acceptance, or the overload protection.

You can also choose the following optional accessories:

- Radio remote control

- Conveyor belt

- hydr. Driving drive

- Magnet – drive drum

- Sieve hydr. foldable

- Reversible fan

- Funnel chest foldable

- Hydraulic support foot

- Vehicle letter

- Special painting (standard RAL 5010) and much more.

Additional Information

Crusher:

- Single-Shaft Crusher with an adjustable working speed of 20 – 40 rpm.

Hydraulic system:

- Hydraulic systems with one tank

- Pumps and motors

- Tank capacity: 190 litres

- Overload protection and auto reverse

Hopper:

- Made of highly wear-resistant steel

- Hopper dimension: 2.200 x 4.000 mm

Shaft diameter:

- 760 mm

Crushing unit:

- 14 cutters

- Shaft diameter: 760 mm

- Shaft length: 2.260 mm

- Bolted, highly wear-resistant shaft scrapers and cutters.

Crushing unit opening:

- 1.200 x 2.260 mm, covered by crushing shaft

Engine:

- CAT turbo diesel with a power of P = 205 kW, valid Euro exhaust standard

- Elektric motor with a power of P = 160 kW

Diesel tank:

- Two tanks, capacity: 300 litres (diesel powered machines)

Drive:

- Optionally diesel-hydraulic or electro-hydraulic, with automatically adjustable auto reverse.

- The slow-speed motor can be operated at a system pressure of 400 bar, thus transmitting a torque of 90.000 Nm up to 130.000 Nm.

Performance control:

- The performance controlled hydraulic system prevents early reversing and optimizes throughput.

Service monitoring :

- Fault indications and required service will be displayed by control lights.

- Transport belt monitoring

- Oil temperature

- Cooling water temperature

- Level display, cooling water circuit, oil circuit

- In case of non-observing the fault indication, the machine cuts out automatically in order to prevent unnecessary damages.

Oil tank heating:

- At temperatures below freezing point, the oil tank heating can be switched on through the mains.

Discharge conveyor:

- Firmly mounted with cross-stable conveyor belt

- Belt width: 1.200 mm

- Discharge height: ca. 3.000 mm

- Foldable for transportation, belt speed infinitely variable

Enquiry Form

Product: Mixed Construction Waste HL I 1222 - Husmann

You may also like

Fine Shredder HFZ - Husmann

Mixed Construction Waste HL I 1230 - Husmann