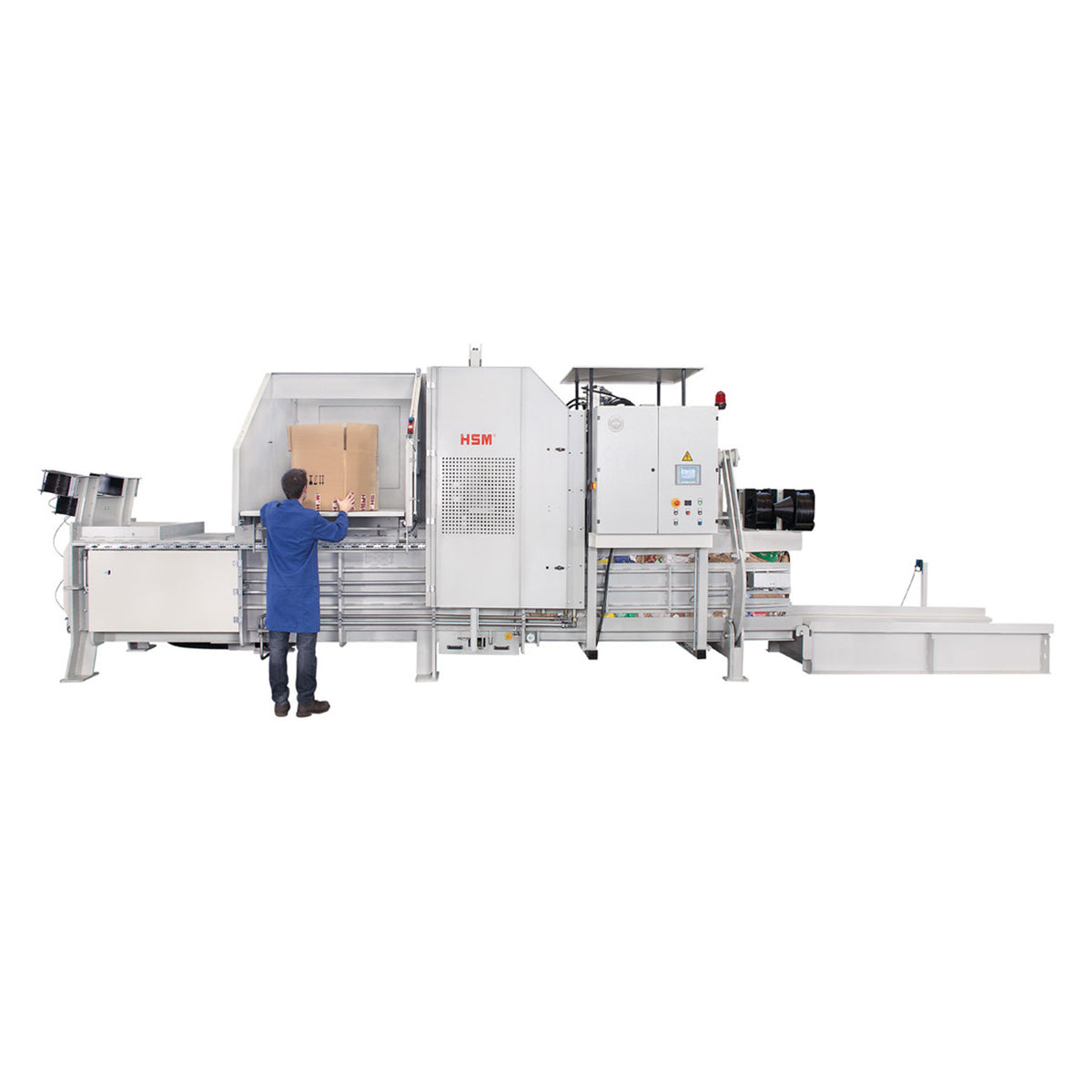

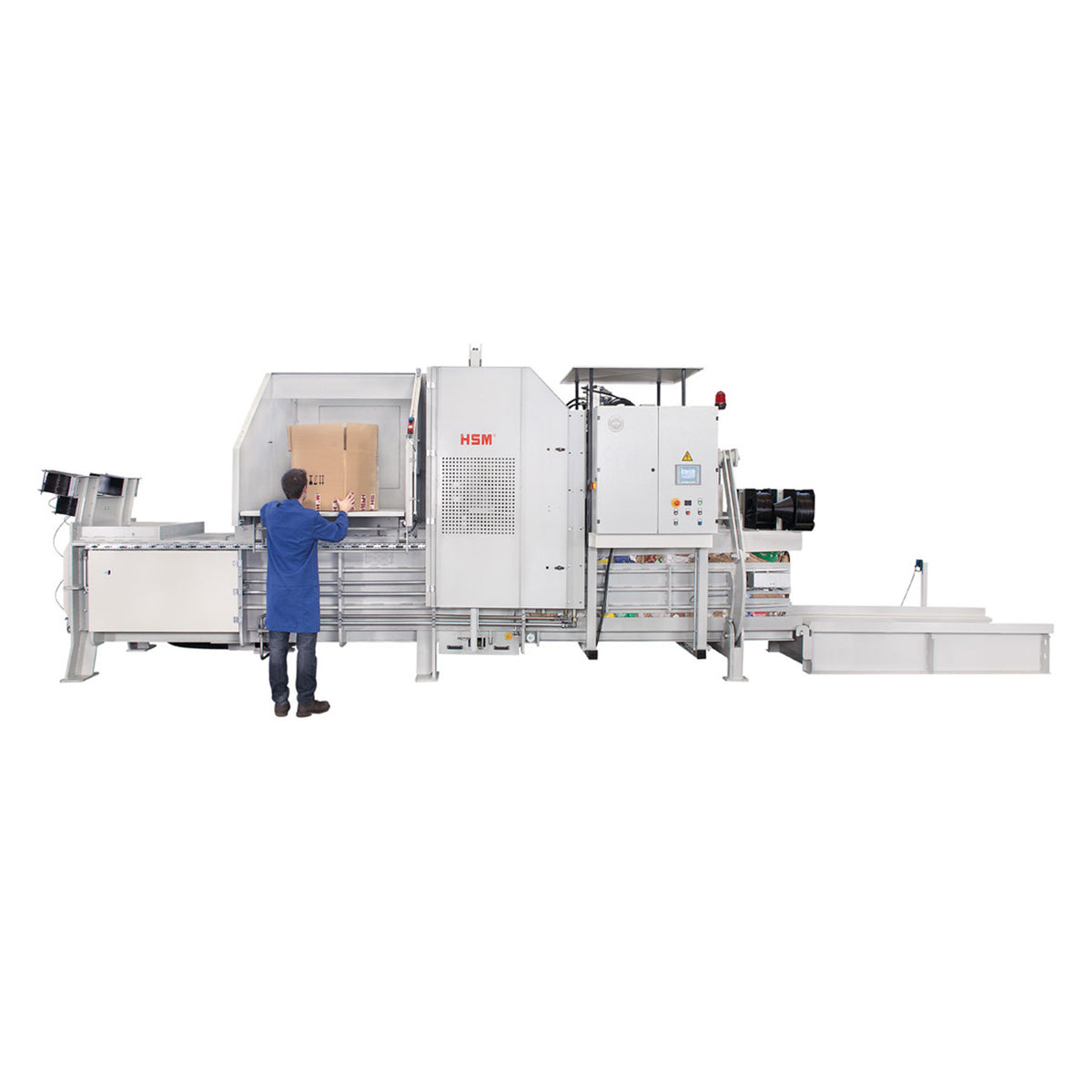

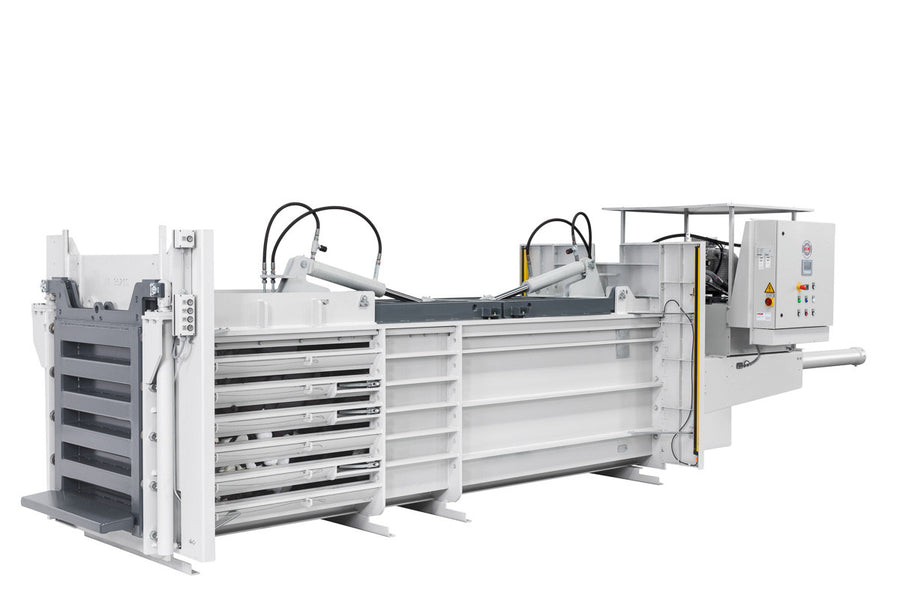

VK4812 Horizontal Auto Tie Baler

Price upon request

For industrial applications with small material loads - Troughput up to approx. 332 m³/h

Features

- Particularly suitable for compression of cardboard and plastic film

- Versatile solution for materials up to approx. 60 kg /m³ bulk weight

- With large loading aperture and higher pressing power

- Integration into automated industrial production processes

- Suitable for continuous loading with conveyor belt, air feeding or similar

- High compression and bale weights

- Control of the pressing process via light barrier

- Can be fully integrated into existing workflows and processes. Operating side can be selected

- Suitable for almost all requirements. Contact us if you have other materials or applications. We will find you a suitable solution.

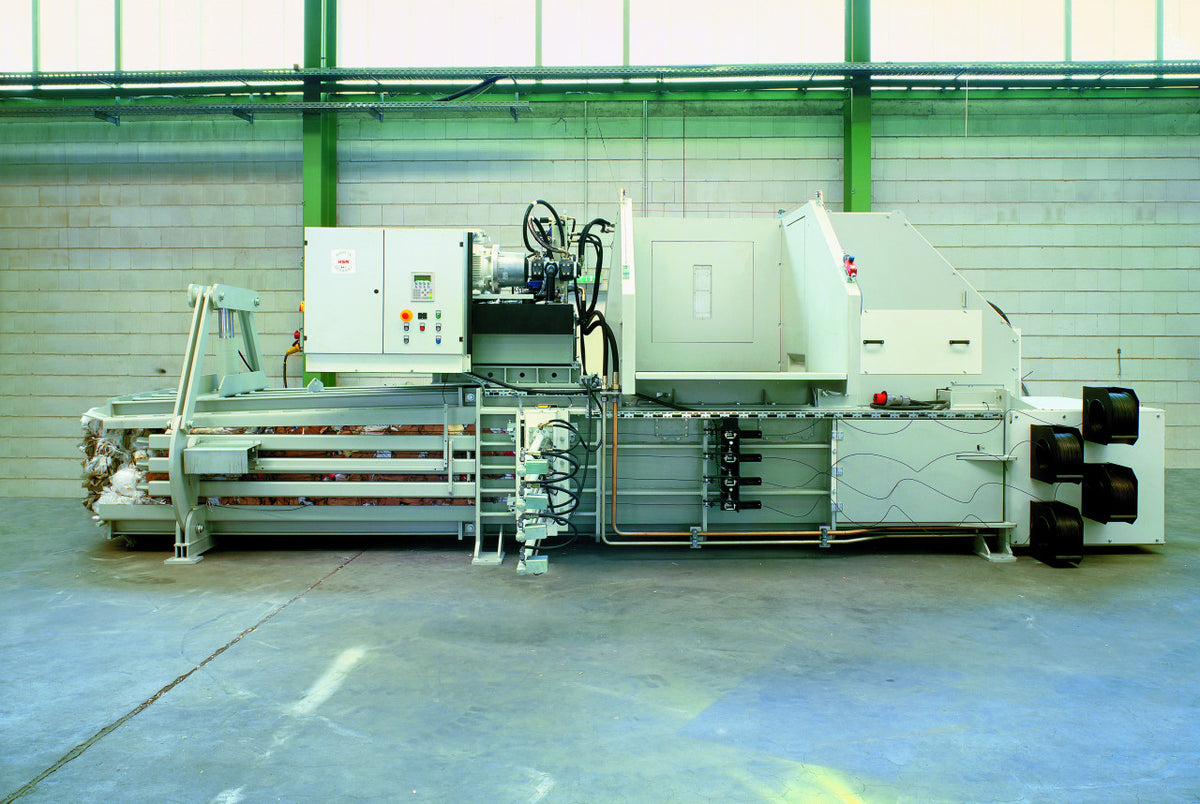

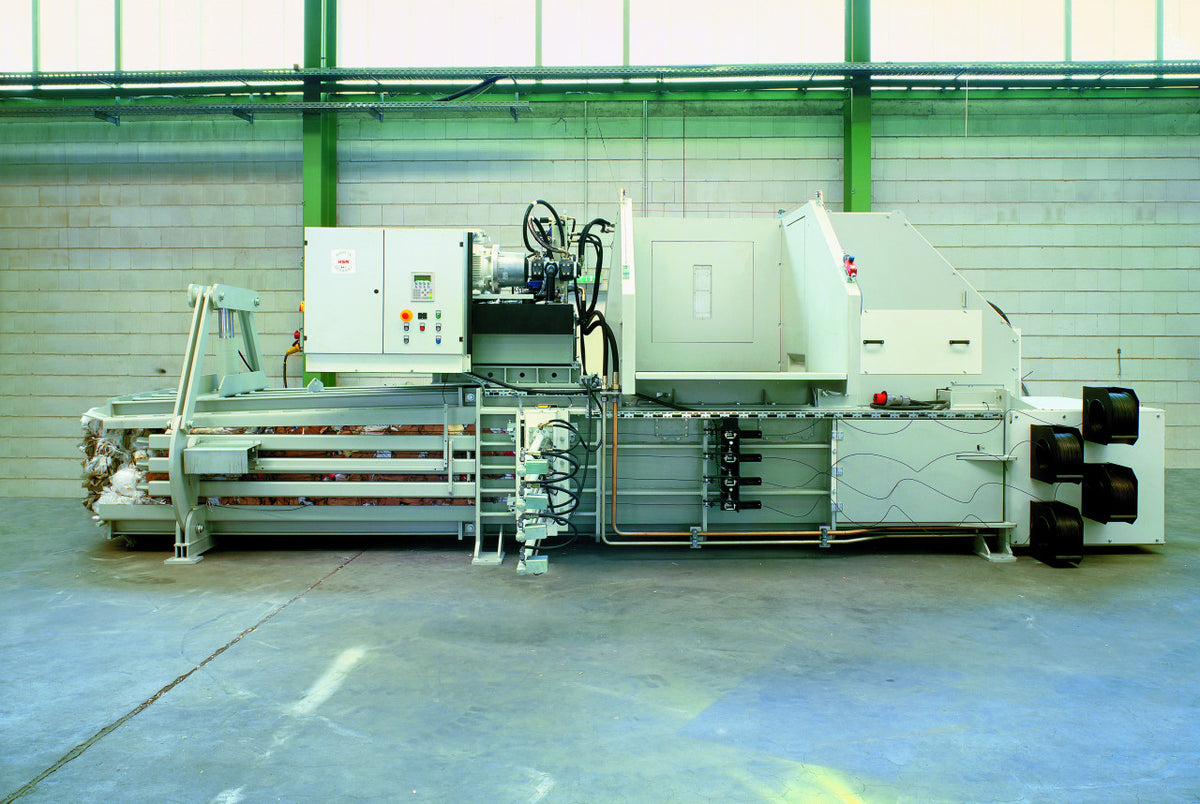

Dimensions

- Width: 3742 mm

- Height: 2400 mm

- Length: 7530 mm

Weight

Machine Weight: 10000 kg

Additional Information

- Pressing power: 480 kN

- Specific pressing power: 58.2 N/cm²

- Driving power: 30 kW

- Voltage / Frequency: 400 V / 50 Hz

- Cycle time when idling vacío: 11.2 s

- Volume throughput in idle operation (theor.): 332 m³/h

- Volume throughput at 50kg/m³ (theor.): 16.6 t/h

- Loading aperture width x Loading aperture length: 1020 x 1250 mm

- Bale width x Bale height x Bale length: 1100 x 750 x 600-1200 mm

- Type of consumables: Wire

- Press material: Plastic film, Mixed paper, Cardboard, Punch waste/residue

Downloads

Enquiry Form

Product: VK4812 Horizontal Auto Tie Baler

You may also like

HL 4812 Horizontal Manual Tie Baler

The HSM HL 4812 has been designed with an operating concept and technical features in mind to make it the optimum machine for food retailers and small central storage facilities....

HL 3521 S Horizontal Manual Tie Baler

The HSM HL 3521 S, with its exceptionally large loading aperture is the perfect machine for compressing large quantities of paper, cardboard, foils or packaging material and for extremely large...

VK4208 Horizontal Auto Tie Baler

For industrial applications with small material loads - Troughput up to approx. 216 m³/h

CC 30 V Horizontal Auto Tie Baler

Due to their compact design PRESTO channel balers, type CC, require little space. They are used to compact large quantities of recycling materials to make stable bales. Stable, stackable bales...

CC 40 V Horizontal Auto Tie Baler

Due to their compact design PRESTO channel balers, type CC, require little space. They are used to compact large quantities of recycling materials to make stable bales. Stable, stackable bales...

SHB1-600-7575 Horizontal Manual Tie Baler For Plastics

This manual tie horizontal baler, also known as a semi-automatic horizontal baling machine, is used for pressing various waste materials, including both solid and hollow plastic material.

SHB1-800-11075 Horizontal Manual Tie Baler

This horizontal manual tie baler, also known as a semi-automatic horizontal baling machine, is used for pressing various waste materials, including both solid and hollow plastic material. It has a throughput...